Publish Time: 2022-03-08 Origin: Site

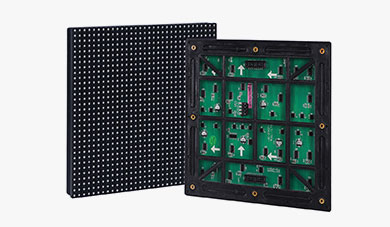

SMD(Surface Mounted Devices) means put SMT(Surface Mount Technology) packing lamps weld on PCB.

DIP(Dual Inline-pin Package) means put the bases of DIP packaging lights through PCB, and fill the pin in lamp holders by welding.

At the beginning of LED screen technology, outdoor LED Display only have DIP Type. The water-proof function , the brightness, moisture-proof and UV protection function.

Performance of DIP display is better than SMD display. The DIP screen quality is more stable.

For production SMD is easy to use automatic machine to produce. Save the labor cost and able to large-scale production. In the future SMD display will be more competitive.

In short, The difference between pixel 10mm for DIP and SMD as follows:

1. Cost for SMD is cheaper than DIP;

2. Quality for DIP is more stable than SMD, outdoor DIP is almost trouble free for the maintenance;

3. Brightness for DIP(about 7500-10 000nits) could be higher than SMD(indoor is from 600-1200nits, outdoor is about 4500-6000nits), so if some customer need higher brightness, DIP is more suitable for outdoor LED display.

4. SMD is widely used for outdoor and indoor both, with various pixels to meet for different environment application, from P0.93, P1.2, P1.5 to P4, P5 for indoor usage, from P2.5, P3, P4 to P8, P10 for outdoor usage.

While DIP is limited to used for outdoor only, in the past there was P10 DIP, P16 DIP and even P20 DIP, and now mostly to use P10 DIP only, P16 DIP and P20 DIP is almost eliminated.

DIP

SMD